Inverter Standards

Many organizations have established standards that address inverter design, safety, performance, mounting, testing, and maintenance. View the standards

An official website of the United States government

Here's how you know

The .gov means it’s official.

Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure.

A lock () or https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

Power inverters convert direct current (DC) power to alternating current (AC) power. Since batteries and solar photovoltaic (PV) modules produce DC power and most common electrical devices require AC power, most systems require inverters to operate.

Inverters may be classified in a number of ways, but especially by the type of AC waveform they produce, their ability to interconnect with the electrical grid, and their intended application (e.g., PV system, battery charging). Inverters are essential for an array of different applications; thus, a range of capacities and features are available on the market. Those who select and operate power inverters with renewable energy and battery storage systems will benefit from the following discussion about types of inverters and applications.

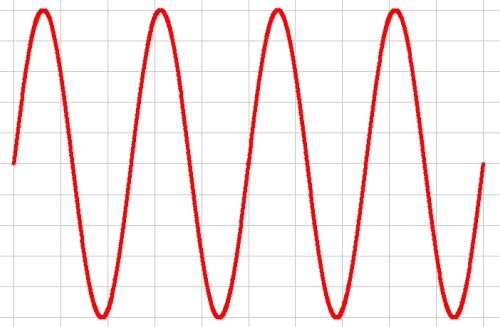

Inverters convert DC power to AC power. DC power, represented by a straight line, can be characterized by its voltage and current. AC power has voltage and current, but is also characterized by its frequency and waveform, with a pure sine wave as the ideal. So an inverter must generate a frequency and waveform from a flat, DC source. Additionally, inverters typically change the voltage of the outgoing AC power, because electrical devices are designed to operate at common grid voltages (e.g., 120 VAC, 220 VAC), while a DC source may operate at up to 1500 V (for a utility-scale PV system) or as little as 12 V (for a battery bank).

AC electrical power is represented by a sine wave, where the current regularly changes direction. The rate of this change in direction is the current’s frequency, which is typically 50 or 60 hertz (Hz), 50 or 60 changes per second. For grid power and generators, the AC sine wave is produced naturally, as electricity is ultimately generated using spinning magnets. Inverters must convert DC power, which has no frequency, to AC power of a specified frequency. There are several approaches to creating AC power, each balancing simplicity with output quality.

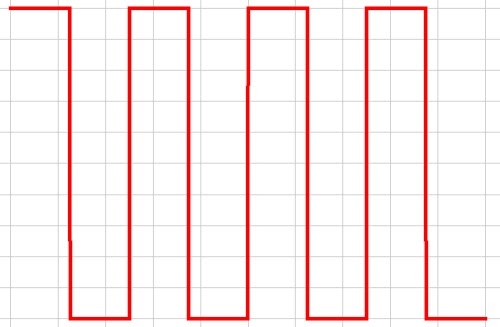

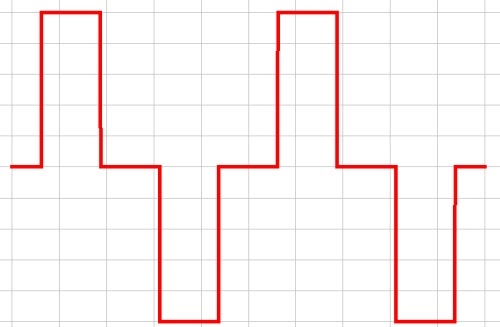

While some inverter technologies can faithfully replicate a pure AC sine wave, others simply produce an approximation. These technologies are categorized in three ways: square wave, modified sine wave, and pure sine wave. The type of loads supported, as well as the type of application, dictates the appropriate technology.

Inverters may also be classified by whether they are able to tie into an electrical grid. Grid-tied (grid-following) inverters are designed to match the frequency and voltage of the electrical grid to which they are connected. In contrast, off-grid (grid-forming) inverters do not adjust their AC output to match an interconnected grid, but rather produce power at a set voltage and frequency.

Grid-tied PV systems are among the most cost-effective ways to deploy PV technology. When interconnecting to the electrical grid, the PV system generates energy that may be used on site, or injected into the grid, ensuring that no PV energy is wasted and negating the need for battery storage. The ability to interconnect with the electrical grid varies from one utility to the next; likewise, the manner in which energy is sold to the grid (net metering, feed-in tariff, etc.) depends entirely on local regulations.

Off-grid inverters do not have the ability to tie into the electrical grid but are designed to serve on-site loads directly, fed from a PV array or battery bank. Off-grid inverters form their own AC sine wave, independent of any other power source.

Inverters are used in any application where a DC power source must be converted to an AC power source. The most common applications are in battery-powered mobile and marine vehicles, uninterruptible power supplies, renewable energy generation systems, and stationary battery banks. These last two applications are described in greater detail.

PV inverters are designed to convert the DC power generated by a solar array into AC power. These inverters are typically used in large-scale (e.g., megawatts) photovoltaic power plants to generate power for the utility grid or in smaller-scale (e.g., kilowatts) solar arrays on roof buildings to offset the building owner’s electricity purchases from the grid. These inverters are not designed to charge and discharge batteries, but employ maximum power point tracking (MPPT), a strategy for maximizing the power production of a PV array. Photovoltaic inverters are designed to accommodate high input DC voltage; some inverters are able to accommodate input voltages of 1,500V.

An important characteristic of battery inverters is their DC input voltage. Battery systems using lead acid batteries typically operate at 12, 24, or 48 V, but some large-scale battery storage systems used by utility companies may operate at 250 V. The higher the battery voltage, the more efficiently the inverter will convert DC power into AC power. Also, inverters designed for use with batteries often include charge control capabilities, allowing the inverter to charge the batteries as needed, using power from the grid or another AC source.

Inverters are designed to deliver AC power as single-phase, split-phase, or three-phase. The phase requirement for any inverter system depends on the configuration of the existing electrical wiring and on the supported loads. Note that many brands also allow single-phase inverters to be linked into groups of two or three via a communications channel, thus enabling them to synchronize their AC output to create split-phase or three-phase power.

Inverters are responsible for many of the active processes that take place in a PV or battery system (e.g., MPPT, battery charging, grid following). They are perhaps the most intelligent component of such systems. They can be programmed, for example, to begin battery charging at a specific state of charge or to sell power to the grid at certain times of the day. These processes can have a profound effect on the performance and longevity of the system; thus, their proper programming is essential to system health.

Many inverter manufacturers offer some form of internet connectivity for their devices, and in some cases, remote system performance monitoring via the internet. This capability is useful for ensuring that the system is working properly and for tracking its performance (e.g., PV generation, battery bank state-of-charge).

Inverters are a common component of many different types of energy systems, so there is a wide range of sizing criteria to consider. Generally speaking, inverters should be sized based on the electrical load they are serving, ensuring that the rated AC output meets the peak power demand on the system. PV inverters, on the other hand, are sized based on their DC input capacity and the peak capacity of the PV system. Because PV systems usually operate below their peak capacity, PV inverters are typically specified to be undersized. An array-to-inverter ratio of 1.2:1 is common, but an experienced professional should determine the size according to site conditions.

Many organizations have established standards that address inverter design, safety, performance, mounting, testing, and maintenance. View the standards